Featured

- Get link

- X

- Other Apps

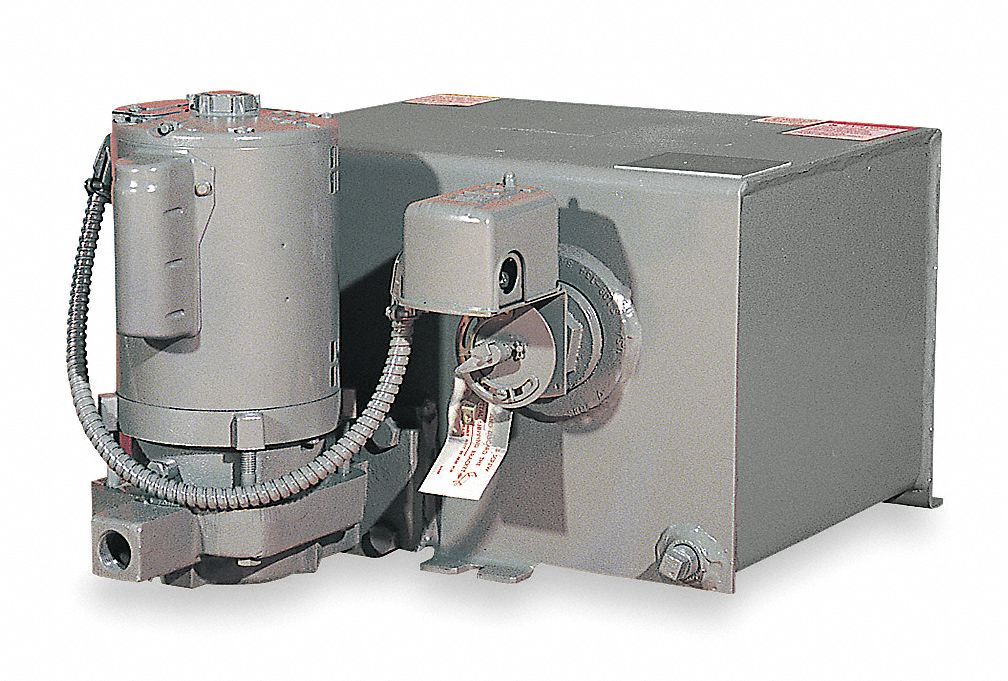

Condensate Return Pump System

Condensate Return Pump System. Benefits of condensate return pump. To provide the highest possible condensate return, type vcs condensate return systems have a 150 gpm pump capacity and a 75 pgis discharge pressure.

Boilersupplies.com stocks units as small as 6 gallon to 500 gallon tanks. Receivers have a low height npt inlet for easy return line piping and a separate npt. Optional accessories include control panels, pressure gauges, isolation valves.

The System Can Also Use Lift Fittings And Drain Low Wetted Return Lines Without An Additional Condensate Return Pump In A Pit.

Specifically designed for high pressure condensate return common in power generation. Another best practice to improve the overall efficiency is by improving the factors. Receiver capacities from 8 (30 liters) to 50 gallons (189 liters) can be supplied on these standard condensate pump units.

In The Boiler Feed Cold Water Is Heated By Mixing With Hot Condensate Return And Pumped To The Boiler On Demand.

Condensate return systems collect condensation generated in a large boiler loop system and pump the condensation back to the boiler. The switch triggers when condensation levels rise, which activates the. Boilersupplies.com stocks units as small as 6 gallon to 500 gallon tanks.

Another Traditional Application For Mth Pumps, Related To Boiler Feed Systems Is Condensate Return Service.

The cast iron receiver includes a 20 year warranty against corrosion. Burks condensate units are designed for automatic return of hot water condensation from radiators, coils, etc. This return temperature is far greater than average feedwater and makeup water temperatures (50ºf to 60ºf).

Condensate Recovery And Return Systems Collect Condensate From Steam Processes And Return It To The Feedwater Tank.

The efficiency of a steam system can be increased by using a condensate recovery system that can contribute to reduced chemical costs and water costs to return condensate to the boiler part. In addition the 3450 rpm motors assure. The pumps are sized for two times the condensing rate.

Most Importantly, The Systems Are Stable And Powerful And Each Unit Features Heavy Gauge Metal And The 3/16” Steel Receivers, Therefore Providing For A Long Operating Life.

Receivers have a low height npt inlet for easy return line piping and a separate npt. A pumping system is required to transport and recover condensate once the system backpressure becomes higher than the lowest possible trap inlet pressure. The grundfos condensate return unit (cru) is a robust design that addresses the most common issues associated with conventional steam cru designs.

Comments

Post a Comment